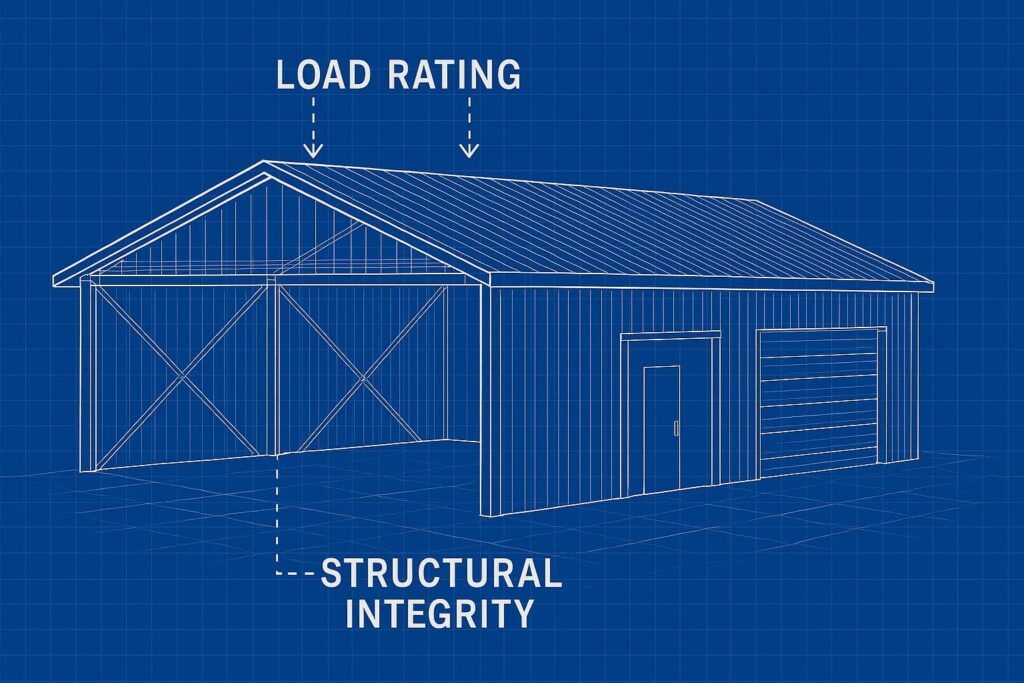

Load Ratings and Structural Integrity in Metal Buildings

- Load ratings define the maximum loads a metal building can safely sustain, including dead, live, and environmental loads.

- Proper connection interfaces like bolts and welds are critical to maintaining structural integrity under various loads.

- Compliance with codes and standards ensures safety, durability, and proper load capacity of metal structures.

- Material quality, design parameters, and foundation compatibility directly influence the building’s load-carrying capacity.

- Regular inspection and maintenance are essential to monitor structural health and prevent failure due to load-related stresses.

Introduction

Structural integrity is a critical consideration in the design and construction of metal buildings, as it guarantees safety, durability, and compliance with engineering standards. Confirming the structural robustness of these structures involves evaluating their capacity to withstand various loads without failure. Load ratings serve as a fundamental metric in this assessment, providing quantifiable measures of a building’s ability to support specific forces. The primary goal is to facilitate well-informed decision-making regarding design parameters, safety margins, and regulatory adherence. By understanding the principles of structural integrity and load ratings, stakeholders can optimize building performance, mitigate risks, and guarantee long-term stability. This foundational knowledge underscores the importance of rigorous engineering practices in developing resilient and compliant metal structures.

What Are Load Ratings?

Dead loads (weight of the structure itself)

Dead loads refer to the inherent weight of a metal building’s components, including framing, roofing, walls, and other fixed elements. These loads are fundamental in determining the building’s overall load capacity and structural stability. Accurate assessment of dead loads is vital for establishing appropriate load ratings, which vary based on regional building codes and intended use. Since dead loads are constant and predictable, they serve as a baseline in structural design calculations. Variations in regional construction practices and material specifications influence dead load weights, affecting the load ratings assigned to different structures. Proper evaluation guarantees that the structure can support its own weight safely, preventing overstress and guaranteeing compliance with safety standards. Understanding dead loads is critical for designing durable, safe metal buildings.

Live loads (occupants, furniture, equipment)

Live loads in metal buildings encompass the weight imposed by occupants, furniture, equipment, and other temporary or movable elements. These loads vary according to building function and regional standards, directly influencing load ratings. Typical live load components include:

- Occupants and personnel, contributing dynamic weight during operational hours

- Furniture and fixtures, such as desks, shelving, and cabinetry

Equipment and machinery, including HVAC units, servers, or manufacturing tools - Accurate assessment of live loads guarantees structural safety and compliance with regional codes.

Load ratings account for maximum expected live loads, which differ based on intended use and location, reflecting regional building regulations and occupancy patterns. Properly specified live loads are vital for designing resilient, durable metal structures capable of accommodating temporary stresses over their lifespan.

Environmental loads (wind, snow, seismic forces)

Key Factors That Affect Structural Integrity

Structural integrity in metal buildings is primarily influenced by material quality, including steel grade, coatings, and corrosion resistance. The choice of materials and finishes not only affects the durability and performance of a steel structure but also its aesthetic appeal.

Design parameters such as truss spacing, column placement, and roof pitch are especially important for steel buildings and steel structures, as the selection of steel components and protective coatings directly impacts their longevity and visual attractiveness. These factors greatly impact load distribution, while foundation compatibility guarantees proper load transfer. Furthermore, connection points (bolts, welds, and fasteners) play a critical role in maintaining overall stability and safety.

Material quality (steel grade, coatings, corrosion resistance)

Material quality plays a critical role in determining the load-bearing capacity and longevity of metal buildings. High-grade steel guarantees superior tensile strength and ductility, crucial for structural stability. Coatings, such as galvanization or paint systems, provide a protective barrier against environmental exposure. When selecting materials and coatings, it is important to consider their ability to withstand high temperatures to ensure the longevity and stability of steel components in extreme conditions. Corrosion resistance is important for maintaining material integrity over time, especially in harsh or humid environments. Key factors include:

- Steel Grade: Higher grades like ASTM A992 or A36 offer improved structural performance.

- Coatings: Protective layers prevent oxidation and reduce corrosion risk.

- Corrosion Resistance: Treatments such as galvanizing extend service life and reduce maintenance needs.

These elements collectively influence the durability and safety margins of metal structures, highlighting the significance of selecting appropriate materials for specific environmental conditions. Additionally, energy efficiency is a key consideration, with high-performance insulation and coatings helping to reduce energy consumption in steel buildings.

Design and engineering (truss spacing, column placement, roof pitch)

Foundation compatibility (how the building interacts with its base)

Foundation compatibility is essential for ensuring that a metal building’s load transfer system functions effectively and maintains long-term stability. Proper interaction between the structure and its foundation prevents uneven settlement, which can compromise integrity. Key factors include:

- Soil bearing capacity: The foundation must be designed to support the imposed loads without excessive settlement or failure.

- Foundation type: Choices such as concrete slabs, piers, or footings must align with soil conditions and structural requirements.

- Compatibility with load distribution: The foundation must evenly distribute vertical and lateral loads, preventing stress concentrations that could lead to cracking or shifting.

Ensuring these elements are accurately assessed and implemented guarantees that the building maintains stability, reduces maintenance costs, and prolongs service life.

Connection points (bolts, welds, fasteners—often overlooked but critical)

Codes, Standards, and Compliance

Compliance with building codes and standards is vital for guaranteeing the structural integrity and safety of metal buildings. Regulatory frameworks include national standards such as the International Building Code (IBC) and ASCE 7, alongside local codes that may specify regional modifications. Adherence requires:

- Collaboration with certified engineers to interpret and apply relevant codes accurately.

- Proper submission of inspection reports and permits, which verify adherence during construction.

- Recognition that “pre-engineered” buildings are not exempt from code compliance, requiring thorough documentation and certification.

These measures guarantee that load ratings are validated, construction practices meet safety criteria, and structures withstand environmental loads. Proper compliance minimizes risks, improves durability, and aligns with legal and safety obligations vital for long-term structural performance.

Real-World Risks of Ignoring Load Ratings

How Load Ratings Influence Design Choices

Load ratings play a pivotal role in shaping the roof styles and structural configurations of metal buildings. The selected roof style—whether a gable or single slope—directly affects the building’s ability to withstand environmental forces like snow and wind, influencing choices around material thickness and the strategic placement of supports. Span width and column spacing are also calibrated according to load ratings, ensuring a balance between efficient material use and structural integrity.

For instance, larger spans typically demand higher load ratings, which may necessitate reinforced beams or trusses to maintain stability. Gable roofs are often favored in regions with heavy snowfall due to their aerodynamic profile, which helps shed snow more effectively. In cases where standard configurations fall short of meeting specific load requirements, custom designs become essential to ensure both safety and code compliance.

Ultimately, these design decisions safeguard the building’s structural durability while aligning with its environmental context and intended function.

Maintenance and Monitoring for Structural Health

Conclusion

Ultimately, load ratings serve as fundamental parameters that underpin the safety, durability, and service life of metal building structures. Proper understanding and application of these ratings are crucial for ensuring structural integrity. Professionals and stakeholders should:

- Recognize that load ratings are integral to design safety margins and compliance with codes.

- Engage early with structural engineers and experts to interpret load data accurately.

- Utilize authoritative resources, such as code guides and engineering checklists, to inform decision-making.