Passive Solar Metal Building Design Guide for Off-Grid Living

Passive solar metal buildings are revolutionizing the way we think about sustainable architecture. By harnessing the energy-saving brilliance of climate-responsive design, these structures aim to maximize energy efficiency, reducing heating and cooling costs while minimizing environmental impact.

This comprehensive guide explores the principles behind passive solar metal buildings, delving into site orientation, material selection, and the integration of current technologies. It also covers innovative passive solar technologies that convert sunlight into thermal energy and utilize natural air movement, further reducing reliance on mechanical systems. Whether you’re a homeowner or a builder, you’ll find actionable insights to create a more sustainable and comfortable living environment.

The Promise and Potential of Passive Solar Metal Buildings

As energy costs climb and concerns about climate resilience intensify, designing a metal building for off-grid living using passive solar principles has become more appealing and achievable than ever. A passive solar metal building combines the durability and modularity of metal construction with the energy-saving brilliance of climate-responsive design. By maximizing solar gain, controlling heat loss, specifying high-performance glazing, leveraging thermal mass, and integrating advanced ventilation, an off-grid dwelling can maintain year-round comfort with minimal mechanical intervention.

This guide will systematically cover the essential design principles, materials, and construction techniques involved in creating a passive solar metal building suitable for off-grid living. Drawing on numerous case studies, current technologies, regulatory considerations, and industry best practices, it provides a practical blueprint for achieving energy independence and environmental harmony in a steel-framed shell.

1. Core Passive Solar Design Principles

1.1 What is Passive Solar Design?

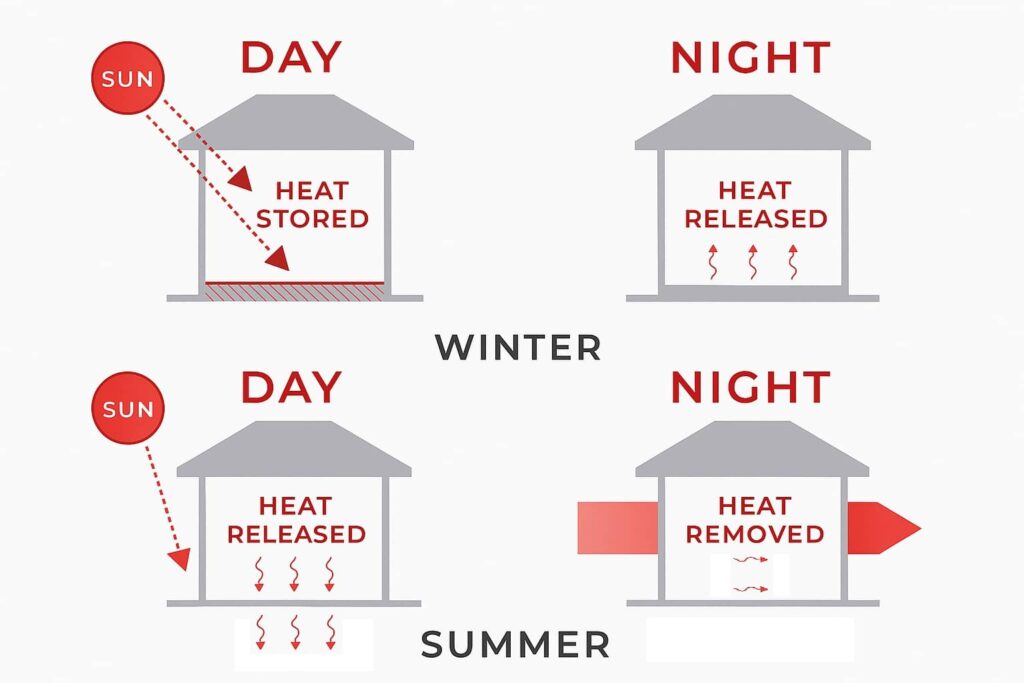

Passive solar design captures and uses the available energy from the sun to heat and cool a building naturally, providing space heating as a primary function and reducing (or even eliminating) the reliance on external power sources. Key components include optimal building orientation, smart window placement, use of thermal mass, strategic insulation, and ventilation.

When these elements are orchestrated correctly:

- Winter sunlight enters through south-facing windows and is absorbed by thermal mass within the building, gradually released for warmth.

- Summer sunlight is blocked or reflected, keeping interiors cooler.

- Lighting costs drop as daylight is harnessed fully.

This process converts sunlight into usable heat for the building, supporting efficient passive solar space heating.

Direct gain systems are the most straightforward approach to passive solar heating, where sunlight enters directly into living spaces and is stored in interior thermal mass.

Passive solar buildings commonly achieve a 20–90% reduction in energy needs compared to conventional construction, with occupant comfort routinely enhanced.

1.2 Building Orientation and Site Positioning

The single most critical step in passive solar design is orienting the building and its windows to maximize solar gain when wanted and minimize it when not.

Site selection should account for overshadowing by trees, hills, or neighboring buildings. Ensuring solar access is maximized—especially from the south—will help the home receive unobstructed sunlight during winter months, which is essential for passive solar performance.

- South-facing windows: Maximize the number and size of windows on the south side to capture winter sun.

- East and west walls: Limit window area on the east and west walls, or use shading devices, to reduce unwanted heat gain and loss. Consider architectural features that help control solar exposure on these walls.

- North side: Minimize window area to reduce heat loss.

The orientation and design of the building envelope are critical for optimizing solar gain and minimizing thermal losses, ensuring energy efficiency and comfort.

Best practices:

- In the Northern Hemisphere, the long axis of the building and most windows should face true south, within 15° for optimal performance.

- East and west façades should have minimal glazing to avoid low-angle sun that is difficult to shade and can lead to overheating.

- North-facing windows typically serve for indirect daylighting and cross-ventilation, not solar gain.

- Site selection should account for overshadowing by trees, hills, or neighboring buildings. If southern exposure is not fully possible, a SE or SW orientation may be acceptable, but solar gain will be less.

- Use solar mapping tools or professional assessments for precise sun angle and exposure duration throughout the year.

The building’s aspect ratio—more rectangular with the long side facing south—maximizes the solar-exposed area.

A well-oriented building may cut heating and cooling costs by up to 85% according to multiple case studies and simulation models.

| Design Element | Description | Benefit |

|---|---|---|

| South-facing long axis | Align building length east-west, facing true south | Maximizes solar gain |

| Minimized east/west windows | Small, shaded openings on side walls | Limits overheating, controls glare |

| Unshaded site area | Open south exposure, unobstructed by landscape | Ensures maximum solar collection |

Site orientation is foundational: it enables all other passive solar strategies to perform at their best.

1.3 Solar-Ready Roof Design

A solar-ready roof is integral both for future photovoltaic (PV) integration and optimizing passive gain. A well-designed roof can also help collect solar energy for both passive and active systems, such as sunspaces or solar panels. Standing seam metal roofs are preferred because they allow attachment of solar arrays with seam clamps, no penetration, no leaks, and no voided warranties.

Critical roof attributes for solar:

- Roof should slope at an angle close to local latitude (~15–45°), facing true south, to capture maximum winter sun.

- Roof surface should be clean, with minimal projections or obstructions (move pipes, chimneys, or skylights to the north or shaded side).

- Plan for sufficient load support: solar panels add approximately 2.5–4 pounds/sq. ft.; as a key example of renewable energy sources integrated into the building, metal buildings can usually handle this, but a structural evaluation is essential, especially in snow or wind-prone climates.

High-reflectivity coatings on metal can reduce summer heat buildup and boost system efficiency. Integrate extra conduit runs for solar at the construction stage to minimize retrofit costs later.

2. Metal Building Materials and Roofing Systems

2.1 Choosing a Passive Solar-Ready Metal Structure

Metal buildings offer several off-grid advantages:

- Extremely low maintenance and high durability (50+ years).

- Recycled content and post-use recyclability.

- Modular, quick to assemble, suitable for remote locations.

- Compatible with both PV and solar thermal technologies.

Roofing:

- Standing seam metal roofing is highly recommended; solar panel mounting systems clamp onto seams, preserving the roof’s waterproof integrity.

- Corrugated or ribbed metal roofs can work; use specialized brackets and waterproof flashings for solar attachments.

- Roof color and coating: High-reflectivity, cool-roof coatings reduce summer heat absorption, improving interior comfort and solar panel output.

Frame system:

- Steel framing allows for greater spans, open interiors, and ease of integrating insulation layers and thermal mass features.

- When optimizing for passive solar, choose framing systems that allow for large southern expanses for windows, overhang structures, and continuous insulation runs with minimal thermal bridging.

2.2 Structural Engineering for Solar-Ready Roofs

A licensed structural engineer must evaluate and confirm:

- The roof and structure can support not just the live/dead loads of the panels, but also additional wind/snow loads induced by PV arrays and any attached overhangs.

- The mounting method for PV arrays suits the specific panel profile (seam height, spacing, panel type) and ensures equal load distribution.

- Local codes (e.g., IBC 2018 and ASCE standards) require load documentation for PV systems; modern code updates may push for higher wind resistance—consult current standards in your region.

2.3 Best Practice Table: Metal Roofing for Solar Integration

| Design Element | Benefit |

|---|---|

| Standing seam roof | No penetrations, fast mounting, matches PV/roof lifespan |

| Clamp-based PV mounts | Structural integrity, reduced labor, maintain waterproofing |

| High-reflectivity paint | Lowers roof temperature, improves comfort and PV output |

| Structural reinforcement | Handles solar + snow, wind, overhang loads, ensures code compliance |

| Pre-installed conduits | Eases PV expansion; reduced costs for future upgrades |

The synergy of metal roofing and solar is unmatched for off-grid and passive designs.

3. Insulation Techniques for Metal Buildings

3.1 The Thermal Challenge

Metal is highly conductive and, without careful insulation, can lead to extreme heat loss in winter, overheating in summer, and condensation inside the building shell.

The right insulation system is essential, it transforms a metal shell from an oven/freezer into a resilient, comfortable home.

3.2 Types of Insulation for Metal Structures

Closed-cell spray foam insulation is considered the gold standard for energy-efficient metal buildings:

- Provides a high R-value (R-6 to R-7 per inch), seamless application, excellent air and vapor barrier, and structural reinforcement.

- Reduces thermal bridging at steel members and prevents condensation/mold.

Other options:

- Foam board insulation (Polyisocyanurate, XPS, EPS):

- High R-value panels (R-5 to R-6.5 per inch), good for walls and roof. Air gap between panel and metal boosts performance.

- Must be fully sealed at all seams and edges for maximum benefit.

- Fiberglass batts (with vapor barrier):

- Cost-effective, moderate performance. Watch for compression, gaps, or moisture issues. Best used with a secondary vapor barrier and overlaid with another rigid insulation layer.

Best results come from combining insulation types:

- For example, closed-cell foam directly on metal, foam board over that, then an interior finish (such as drywall or ply).

- Ensure entire envelope—including roof, walls, and under the floor slab—is insulated and well-sealed.

Key Insulation Methods and Benefits

| Method | R-Value / Benefit | Special Concerns |

|---|---|---|

| Closed-cell spray foam | R-6 to R-7/inch; structural, air/vapor barrier | Can restrict roof panel movement; must coordinate with roof type |

| Foam board (polyiso/XPS) | R-5 to R-6.5/inch; moisture resistant | Gaps must be tightly sealed; ignition barrier needed |

| Fiberglass batts w/barrier | R-3 to R-4/inch; cost-effective | Vulnerable to gaps, compression, moisture; always add vapor barrier |

| Combination system | R-25–R-60 achievable; optimal air tightness | Must watch for fire code compliance inside |

Many leading case studies (Eco-Friendly Home B, Solar House A, Saft Passive House) use R-60+ in roof, R-40/80+ in walls, and R-20+ below grade.

3.3 Addressing Thermal Bridges

Thermal bridging occurs when steel elements pass uninterrupted through the insulation, creating a direct pathway for heat loss. To mitigate this, several strategies can be employed. One effective method is the use of thermal break pads—such as high-strength composite inserts- at structural penetrations to interrupt the conductive path. Ensuring continuity in exterior insulation is also key; the more insulation is placed “outboard” of the structure, the better its thermal performance. Window and door frames should be specified with integrated thermal breaks to prevent energy leakage at openings. Additionally, using insulated fasteners and minimizing direct metal-to-exterior connections wherever possible helps preserve the building envelope’s integrity.

Ultimately, effective insulation in a passive solar metal building goes far beyond R-value. Installation quality, airtightness, moisture control, and the elimination of thermal bridges are equally critical to achieving high performance and occupant comfort.

4. Thermal Mass Integration in Metal Structures

4.1 What is Thermal Mass, and Why is it Essential?

Thermal mass in passive solar design acts as a battery, absorbing, storing, and releasing solar heat as temperatures fluctuate.

- Materials: Concrete, masonry, brick, tile, and even water tanks. The denser, the better.

- Placement: Mass must be inside the insulated envelope and within the path of winter sunlight (direct gain).

Benefits:

- Reduces daily temperature swings, smoothing out sunny/cold spells.

- Stores daytime heat for release at night during winter.

- Can absorb excess heat during summer, helping keep interiors cool.

Ideal thickness for standard concrete within metal buildings is 75–100mm (3–4″) [the optimal depth for daily heat flux.]

4.2 How to Add Thermal Mass to a Metal Building

In passive solar design, thermal mass plays a crucial role in regulating indoor temperatures and storing solar energy. A slab-on-grade concrete floor is the most common and effective option, often finished with polished, dyed, or tiled surfaces to enhance aesthetics while maintaining functionality. Interior masonry feature walls, made of brick or concrete, are typically placed opposite large south-facing windows, allowing them to absorb and distribute solar heat evenly throughout the space. Additional thermal mass can be incorporated through interior stone or tile finishes on floors, walls, or even built-in benches. While water tanks can also serve as thermal mass, they are less commonly used due to structural and safety concerns.

To maximize performance, thermal mass must be exposed to direct sunlight during winter days and insulated from the exterior. For optimal results, insulation should be located outside the thermal mass. This configuration helps retain warmth within the living space, enhancing comfort and energy efficiency throughout the building.

5. Window Placement and High-Performance Glazing

5.1 Strategic Window Design for Passive Solar Performance

Windows play a pivotal role in passive solar design; they’re the primary gateway for capturing solar heat during colder months, but they can also become the building’s biggest source of heat loss or unwanted gain if not thoughtfully engineered. Their placement, size, glazing type, and shading strategy all influence how effectively they contribute to energy efficiency and occupant comfort.

South-facing windows are especially valuable for harnessing winter sunlight, but without proper shading, they can lead to overheating in summer. That’s where sun-controlling overhangs or adjustable awnings come in. These architectural features are not just aesthetic; they’re functional tools that respond to seasonal sun angles. Fixed overhangs can be sized to allow low-angle winter sun to penetrate deep into the interior, warming thermal mass surfaces like floors and walls. In contrast, during summer, when the sun is higher in the sky, these same overhangs block direct rays, keeping interiors cooler and reducing the load on mechanical cooling systems.

Adjustable awnings or operable shading devices offer even more flexibility, allowing occupants to fine-tune solar exposure based on weather conditions or daily use patterns. When paired with high-performance glazing and well-insulated frames (ideally with integrated thermal breaks), windows can become powerful contributors to a building’s passive solar strategy—balancing light, heat, and comfort year-round.

Principles:

- South-facing glazing (in the Northern Hemisphere): Largest window areas, 7–12% of floor area, focus on main living spaces.

- East and west windows: Minimize window area; morning/evening sun is difficult to shade, more likely to cause overheating.

- North windows: Small, used for diffuse daylight. Avoid large north windows in cold climates.

Window-to-wall ratio guidance:

- South: 50 – 60% of total glass area

- North: 20 – 30%

- East & West combined: <20%

5.2 Advanced Glazing Technologies for Solar Heat Gain

Select windows with the lowest U-values (highest R-values) and appropriately tuned Solar Heat Gain Coefficient (SHGC):

- Triple-pane, argon/krypton-filled, Low-E coated windows are the current gold standard; windows like Zola’s Arctic™ series (R-11), PHIUS/PHI certified, are now widely available in North America.

- Thermally broken, insulated frames (wood, vinyl, or aluminum with foam inserts) prevent cold bridging and condensation.

Dynamic glazing/smart glass, aerogel ‘super windows’, and advanced vacuum panels are emerging, promising even better insulation and solar management without excessive window bulk.

Shading can be further enhanced by exterior roller blinds, blinds, or deciduous landscaping. Automated systems respond to conditions, maximizing year-round benefit.

Window Placement and Glazing Strategies

| Design Element | Benefit |

|---|---|

| South-facing glazing | Maximizes winter heat gain, daylight |

| Triple/quad-pane, Low-E | Minimizes heat loss and condensation |

| Thermally broken frames | Stops cold bridging, improves comfort |

| Overhangs/awnings | Block high summer sun, allow winter light |

| Smart glass/aerogel | Further cuts energy losses, improves flexibility |

| Strategic shading | Prevents overheating, controls glare |

6. Ventilation Strategies for Metal Buildings

6.1 The Role of Ventilation in Metal Structures

Proper ventilation in a tightly sealed, super-insulated metal building is essential, not just for comfort, but for long-term durability and occupant health. Without adequate airflow, these buildings can quickly become vulnerable to a range of issues. Overheating is a common problem in summer, driven by solar gain and the high thermal conductivity of metal surfaces. Moisture buildup is another concern, often leading to what’s known as “sick-building syndrome,” where mold, odors, and elevated CO₂ levels degrade indoor air quality and create an unhealthy environment.

Perhaps most critically, poor ventilation allows condensation to form on cold surfaces. In metal buildings, this can trigger rust, compromise insulation performance, and even contribute to respiratory issues. That’s why ventilation systems must be carefully integrated into the design, balancing airtightness with controlled, strategic airflow to maintain a healthy, efficient, and resilient building envelope.

6.2 Natural, Mechanical, and Hybrid Solutions

Best practice: Use a hybrid approach, maximize natural ventilation when conditions allow, but include mechanical heat/energy recovery for consistent year-round performance.

- Natural (passive) ventilation: Ridge vents, soffit vents, wall louvers, operable windows, and stack effect design utilize wind and thermal currents to exhaust heat and draw in fresh air.

- Mechanical ventilation: HRV/ERV (Heat/Energy Recovery Ventilator) units provide continuous fresh air, capturing up to 93 – 95% of exhaust heat for energy-neutral air exchange; Zender and Ultimate Air RecoupAerator are leading models.

- Hybrid/mixed-mode: Operable vents for shoulder seasons plus HRV for summer/winter, with smart controls for CO2, humidity, and temperature. Electronic sensing devices are often used in these systems to monitor and optimize ventilation and heat distribution, ensuring efficient operation and occupant comfort.

Balance intake and exhaust for steady airflow; avoid depressurization that can draw in moisture from the ground or introduce drafts.

Key Ventilation Solutions for Metal Buildings

| System Type | Best For | Advantages |

|---|---|---|

| Ridge/soffit vents | Simple, low-cost, rural applications | No energy use, year-round airflow |

| HRV/ERV units | Year-round, airtight homes | Fresh air, energy recovery, filter options |

| Hybrid (vents + HRV) | Variable climates, mixed-use buildings | Flexible, efficient, consistent indoor air quality (IAQ) |

Regular maintenance and proper placement of vents prevent issues and ensure the longevity of insulation and structure.

7. Electrical Infrastructure for Off-Grid Metal Buildings

7.1 Integrated Solar Electrical Planning

For off-grid living, designing the electrical infrastructure from the outset is critical to ensure long-term safety, efficiency, and reliability. Every component, from conduit runs to backup systems, must be thoughtfully planned to support both current needs and future expansion.

Start by pre-planning conduit routes from the roof-mounted solar array to the inverters and main electrical panel. Ideally, use 1-inch metal conduit with minimal bends to simplify future wiring upgrades and reduce installation labor. Allocate dedicated space for key components, including solar and battery inverters, backup generators, battery banks, control systems, and optional charge controllers or fuse panels. These elements should be easily accessible and well-ventilated to support safe operation and maintenance.

Grounding is especially important in metal structures, where special bonding techniques must be used to prevent electrical faults and ensure code compliance. All wiring and conduit materials should be rated for temperature extremes, UV exposure, rodent resistance, and fire safety, especially in remote or wildfire-prone areas.

Finally, plan the layout of all electrical components with accessibility and safety in mind. This includes clear pathways for monitoring, emergency shutoff, and fire containment. A well-designed system not only supports energy independence but also protects the integrity of your building and the well-being of its occupants.

7.2 Battery Storage Solutions and Off-Grid Power

For true off-grid function, battery storage is indispensable.

Options:

- Lithium-ion batteries: High energy density, long life, modular, safe with correct BMS. Common brands: Tesla Powerwall, Enphase, DIY prismatic systems.

- Lead-acid (AGM, flooded): Budget option, shorter life, regular maintenance needed.

- Flow batteries: Emerging for larger, stationary applications.

Best Practice:

- Right-size your battery bank to provide for 1–3 days (or more) of autonomy, considering climate and loads.

- Include a Battery Management System (BMS) for safety—prevents overcharge, deep discharge, and overheating.

- Install a battery monitoring system for real-time performance.

- House batteries in vented, weather-protected, fire-rated enclosures with safety labeling per code.

7.3 Off-grid System Sizing and Layout

- DC/AC inverter(s): Powers house loads; solar-compatible inverters for PV input.

- Charge controller: Matches PV array output to battery bank specs.

- Back-up generator: Optional for extended periods with low sunlight.

- Smart controls and whole-building monitoring: For optimization and remote alerts.

Professional design and installation are strongly recommended for safety, code compliance, and insurance coverage (NEC 2021, IBC, local variations).

Electrical and Battery Infrastructure Essentials

| Component | Function | Best Practice |

|---|---|---|

| Solar-ready conduit | Future-proofs building for PV expansion | 1″ metal, straight-run, clearly labeled |

| Inverter space | Houses inverter, meter, controls | Accessible, dry, vented, and code-compliant |

| Battery enclosure | Protects and vents batteries | Fire-rated and properly ventilated |

| Battery bank (Li/Lead) | Energy storage | Integrated Battery Management System (BMS), right-sized |

| System monitor/controller | Tracks performance, shut-off, optimization | Smart-enabled and networked for remote access |

8. Cost Analysis and Financial Incentives

8.1 Upfront Costs

- Metal building kits (shell only): $10–$25/sq.ft. for materials; fully erected $24–$43/sq.ft. nationally.

- High-end insulation (walls R-40 to R-80, roof R-60+): Adds $3–$7/sq.ft., about $8,000–$20,000 for a 2,000 sq.ft. home.

- Solar system: $2.50–$4.50/watt; a 10 kW system costs $25,000–$45,000 installed before incentives.

- Battery storage: $10,000–$20,000 or more, depending on capacity and chemistry.

- Passive solar design and consulting: 1–3% premium compared to conventional custom design.

8.2 Long-Term Performance and Incentives

- Federal Tax Credits: 30% off solar/battery systems (through at least 2025); 100% sales tax exemption in some states (e.g., Colorado); property tax exclusion for solar upgrades.

- Utility/State Rebates: US rebates range from $250-$2500/kW installed; net metering (where available) further reduces operating costs.

- Energy savings: Passive designs routinely cut total energy expenses by 60–85% compared to code-minimum buildings—full payback in 5–12 years depending on system size and location.

Cost and Incentive Overview

| Element | Initial Cost | Incentives | Payback / ROI |

|---|---|---|---|

| Metal building shell | $20–$40/ft² | None | 50+ year lifespan |

| High-performance insulation | $3–$7/ft² | Weatherization programs | Immediate comfort, long-term energy saving |

| Solar system (10 kW) | $25k–$45k | 30%+ tax credits, utility rebates | 6–12 years |

| Battery storage (10 kWh+) | $10k–$20k | 30%+ tax credits | Ensures true off-grid security |

9. Smart Materials and Advanced Technologies

Emerging options for even greater performance include:

- Aerogel glazing for windows and insulated frames: delivers super-low U-values with slim profiles.

- Dynamic/switchable glazing (chromogenic/glass): Adjusts tint to keep heat in or out automatically.

- Building-integrated photovoltaics (BIPV): PV built directly into roofing or wall panels for seamless integration and combined weather and energy performance.

- Smart thermostats and home automation: Reduce heating/cooling bills further (10–20% savings typical).

Digital modeling and energy software (PHPP, EnergyPlus, WUFI Passive, BEopt, TRNSYS, etc.) enable optimization and viral testing of different envelope and energy system designs before construction, ensuring systems meet performance and ROI targets. These tools are especially valuable for optimizing passive systems, allowing designers to fine-tune architectural elements, materials, and climate-responsive features for maximum energy efficiency without relying on mechanical systems.

10. Energy Modeling and Simulation Tools

Energy modeling is indispensable for modern passive solar metal building design:

Best-in-class tools:

- WUFI Passive: North-American optimized, certified for Passive House modeling; incorporates heat, moisture, and dynamic simulation.

- EnergyPlus/DesignBuilder: Open-source/hourly simulation, comprehensive modeling for envelope, HVAC, PV, daylighting, and thermal mass.

- PHPP (Passive House Planning Package): Gold standard for passive house, spreadsheet-based, widely used internationally.

- BEopt (NREL): Cost-optimization for high-performance and net-zero residential building design.

- TRNSYS: Advanced, research-focused; simulates renewables, HVAC, control strategies, and thermal storage.

All provide quantifiable predictions of annual energy use, heat flow, window and insulation effects, as well as modeling of solar radiation and thermal energy dynamics in the building, and allow informed, climate-specific decision making.

11. Building Codes and Regulatory Considerations

Compliance with building codes is a foundational step in designing any high-performance or off-grid structure. National standards like the IBC and IECC, along with local and state variants, often dictate minimum requirements for insulation levels, fire resistance, wind and snow load capacity, battery sizing and placement, and solar wiring provisions. Staying current with these regulations is essential, as they evolve to reflect new technologies and climate considerations.

Many states now enforce solar-ready mandates, requiring new construction to include designated solar zones on rooftops, pre-installed conduit runs, and infrastructure that supports future battery integration. These requirements not only streamline future upgrades but also align with incentive programs and energy efficiency goals.

Safety is another critical dimension. All solar and battery energy storage systems (BESS) must include code-compliant fire detection and suppression systems, proper battery venting, and clearly labeled rapid shutdown mechanisms to protect occupants and first responders. Permitting and documentation also play a major role—designs must be backed by load calculations, energy models, and formal approval from certified engineers and licensed electrical contractors.

To navigate this landscape successfully, professional collaboration is key. Working with experts in Passive House design and solar integration ensures that your project meets all regulatory requirements, qualifies for available incentives, and avoids costly redesigns or compliance setbacks down the line.

12. Integration Tips and Common Mistakes

- Engage an architect/engineer and solar contractor with metal building AND passive solar experience.

- Overemphasis on just solar gain leads to summer overheating—balance with shading, controls, and venting.

- Avoid under-specification of insulation and window performance; skimping here undermines every other investment.

- Plan for future needs: oversize wiring/conduit, roof reinforcement, and space for battery expansion.

- Sequence window, door, and penetrations so that air/vapor barriers are never compromised.

Careful, holistic planning delivers year-round comfort, robust energy independence, and long-term financial sustainability.

Key Passive Solar Metal Building Elements and Their Benefits

| Design Element | Description | Primary Benefit |

|---|---|---|

| South-facing orientation | Main axis and windows face true south | Captures maximum winter solar gain |

| Standing seam metal roof | Seam-clamp solar mounting, high durability | No penetrations, lifetime match, easy expansion |

| High-performance insulation | R-40–80 walls, R-60+ roof, slab/floor R-20+ | Year-round comfort, huge energy savings |

| Exterior insulated slab/mass | Concrete/slab inside, insulation outside | Smooths indoor temperature, stores/absorbs heat |

| Triple-pane windows, Low-E | High R-value (5–9), tuned SHGC by orientation | Low heat loss, maximum daylight, comfort |

| Overhangs/awnings/deciduous shade | Summer shading for south glass | Cuts summer gains, eliminates overheating |

| HRV/ERV with full heat recovery | Fresh air, balanced pressure, low energy use | Excellent air quality with minimal heat loss |

| Battery bank (Li/other BESS) | Modular, vented storage for solar backup | True off-grid capability, peak load resilience |

| Pre-wired PV conduit | 1”+ metal pathways from roof to inverter | Simplifies PV install, future-proofs energy system |

| Modular system design | Roof/conduit/battery sized for expansion | Scalable energy, adaptable to changing needs |

| Energy modeling (WUFI/PHPP/etc) | Pre-construction simulation, optimization | Validated comfort, code, and ROI performance |

| Solar tax incentives | Utilize all available federal/state utility $ | 30–50% lower upfront costs, faster payback |

| Professional design team | Engineer, builder, solar, architect synergy | Ensures compliance, warranty, code, and performance |

Conclusion: Passive Solar Metal Buildings - Delivering Off-Grid Comfort and Resilience

Designing a passive solar metal building for off-grid living is a multidisciplinary challenge, one made easier today by robust case studies, advanced modeling tools, improved materials, and clear regulatory support. By thoughtfully integrating orientation, advanced insulation, strategic window placement, thermal mass, ventilation, and state-of-the-art electrical/battery infrastructure, it is possible to achieve comfort, health, and self-sufficiency in a building that will last for generations.

When every design decision is made in harmony with the sun, the climate, and the best construction science, the result is not only a zero (or even positive) energy building, but also a profoundly resilient and pleasurable home, whatever the weather or circumstance.

The future of sustainable, off-grid living is now metal-clad—sun-powered, comfort-optimized, and ready for whatever tomorrow brings.

Inspired by what you read?

Whether you’re planning an energy-efficient home, a resilient off-grid retreat, or a solar-ready commercial space, the right metal building design makes all the difference. At ROI Metal Buildings, we specialize in structures that go beyond the basics, helping you to integrate passive solar strategies, high-performance insulation, and future-proof energy systems tailored to your goals.

From concept to completion, our team helps you navigate code compliance, optimize for your climate, and design for long-term ROI. Grid-tied or off-grid, we’ll help you build a space that’s comfortable, durable, and ready for what’s next.

Let’s turn your vision into a high-performance reality. Fill out the form below to start your custom metal building consultation, your future space is just a few clicks away.