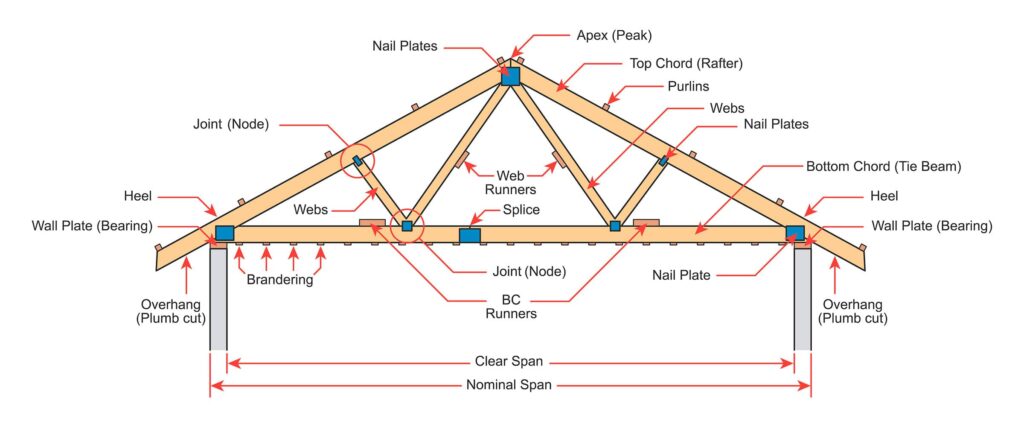

Parts of a Roof Truss Explained

Roof trusses integrate multiple engineered components to optimize load distribution and reduce costs by 20-30% versus traditional rafter systems. Key elements include the apex (peak) for load convergence, top and bottom chords for primary support, and web members for internal stabilization. BC runners and purlins provide essential bracing, while wall plates guarantee proper bearing. Brandering facilitates efficient ceiling attachment. Understanding these structural components reveals vital engineering and cost considerations for practical truss construction of wood or steel buildings.

Continue reading to learn detailed definitions of the different parts that make up a roof truss. For a better understanding of these components and their locations, please refer to the image below, which provides a clear visual guide of roof truss parts and their positioning.

Jump to Subject

Apex (Peak)

The apex represents the highest point of a roof truss system where the top chords converge. This critical junction requires precise engineering to guarantee ideal load distribution and structural integrity. Proper apex design directly impacts construction costs through material efficiency and labor requirements.

The apex joint typically incorporates heavy-duty nail plates sized according to calculated stress levels and load-bearing requirements. Strategic apex positioning affects overall truss height, pitch angles, and spanning capabilities. When specifying apex connections, engineers must account for regional snow loads, wind forces, and dead loads. Careful attention to apex detail reduces the risk of structural failure while maintaining cost-effective design parameters.

BC Runners

Longitudinal stability in truss systems depends heavily on BC runners, which are horizontal members connecting the bottom chords between adjacent trusses. These components serve as critical bracing elements, reducing the risk of truss rotation and ensuring proper load distribution across the system.

BC runners optimize cost efficiency by minimizing the need for additional lateral support mechanisms. They effectively transfer horizontal forces between trusses when properly specified and installed at prescribed intervals. Industry standards typically require BC runners to be engineered lumber of sufficient grade and dimension to resist compression and tension forces. Strategic placement of these members reduces installation labor while maintaining structural integrity.

Bottom Chord

Running along the lower horizontal plane of a truss system, bottom chords serve as primary load-bearing members that support ceiling dead loads and live loads. These crucial components transfer tensile forces through the truss system while maintaining structural integrity and dimensional stability.

Bottom chords require precise engineering to handle specific load calculations, including drywall weight, insulation, lighting fixtures, and potential storage loads in attic spaces: the member size and grade specifications directly impact material costs and overall truss performance. Proper connection to wall plates via heel joints and strategic placement of nail plates at critical intersections guarantees ideal load distribution throughout the structural assembly.

Brandering

While bottom chords provide primary structural support, brandering components serve as intermediate support members installed perpendicular to roof trusses. These secondary structural elements create a framework for direct ceiling attachment, optimizing installation efficiency and cost-effectiveness.

Brandering typically consists of timber battens or metal channels fixed at specified intervals, typically 400mm or 600mm centers. This configuration facilitates secure fastening of ceiling materials while distributing loads uniformly across multiple trusses. The strategic placement of brandering members reduces material waste, minimizes deflection, and guarantees proper ceiling alignment. Correct brandering specification is critical for achieving building code compliance and long-term structural integrity.

Clear Span

The clear span measurement represents the critical distance between the interior faces of supporting walls, directly impacting truss design specifications and material costs.

This measurement differs from the nominal span, as it excludes wall thicknesses and bearing surfaces. Engineers and contractors must accurately determine clear span dimensions to guarantee proper truss sizing and load distribution. A miscalculation can result in structural inadequacies or unnecessary material expenditure.

Professionals factor in wall construction methods, bearing requirements, and local building codes when calculating clear span. This precise measurement facilitates ideal truss design, maximizing structural efficiency while minimizing overall project costs through accurate material ordering and waste reduction.

Heel

Structural integrity within roof trusses heavily depends on the heel joint, which forms the critical connection point where the top and bottom chords intersect at the wall plate. This junction transfers compressive and tensile forces from the roof load to the supporting wall structure.

Professional engineers specify heel height requirements based on load calculations and local building codes. Inadequate heel height can compromise load distribution and increase stress on nail plates, potentially leading to costly structural failures. Ideal heel design reduces material waste while maintaining the required bearing capacity. Metal connector plates at the heel must be properly sized and installed to guarantee long-term performance and code compliance.

Joint (Node)

Critical intersection points, known as joints or nodes, serve as essential connection locations where two or more truss members meet and transfer forces throughout the assembly. These connections typically utilize metal nail plates to secure the intersecting components and guarantee proper load distribution.

Each joint must be engineered to withstand specific design loads while maintaining structural integrity. The precise placement and sizing of nail plates at these intersections directly impact material costs and assembly efficiency. Proper joint design minimizes waste, reduces labor requirements, and optimizes overall truss performance. Industry standards require joints to meet strict quality control specifications for both residential and commercial applications.

Nail Plate (Wood Construction)

Metal connector plates with punched teeth, known as nail plates, provide an economical and efficient method for joining truss members at critical intersection points. These galvanized steel fasteners transfer loads between intersecting wood members while maintaining structural integrity at each joint.

Manufacturers produce nail plates in various sizes and configurations to accommodate different load requirements and member sizes. The teeth are hydraulically pressed into the wood during fabrication, creating permanent connections that eliminate the need for traditional nailing or bolting. This standardized joining method reduces labor costs, guarantees consistent quality control, and facilitates rapid mass production of engineered roof trusses.

Nominal Span

The nominal span is the primary measurement used in truss design and cost estimation. It extends from heel to heel on opposite ends of the truss assembly. This critical dimension differs from the clear span, as it includes the bearing width at each support wall. Engineers and manufacturers utilize nominal span calculations to determine material requirements, load distributions, and pricing structures.

For accurate cost analysis and structural integrity, designers must account for the relationship between nominal span and other truss components, including web configuration, chord sizes, and joint placement. This measurement serves as a fundamental reference point in truss engineering specifications and building code compliance documentation.

Overhang (Plumb Cut)

Beyond the nominal span, roof truss overhangs extend the top chord past support walls to create protected eaves and architectural details. The plumb cut at the overhang provides a clean vertical termination point that improves water management and aesthetics while reducing material costs compared to field-fabricated alternatives.

Standardized overhang lengths typically range from 12 to 36 inches, with longer spans requiring additional engineering considerations and bracing. Proper overhang design must account for wind uplift forces, snow loads, and local building codes. Factory-engineered overhangs deliver consistent quality control and eliminate time-consuming on-site modifications, resulting in accelerated installation schedules.

Purlins

Structural purlins form critical intermediate supports between roof trusses, transferring loads from roofing materials to the primary truss system while reducing individual truss requirements. These horizontal members optimize cost efficiency by enabling wider truss spacing and lighter truss designs, resulting in material savings of 15-25%.

Purlins typically consist of dimensional lumber or engineered wood products, sized according to span and load requirements. Strategic placement at key points along the top chord guarantees effective load distribution. Industry standards recommend purlin spacing at 4-6 feet on center, with cross-bracing at specified intervals to prevent lateral movement and maintain structural integrity.

Splice

While purlins span between trusses horizontally, splice connections address lengthwise adaptations in truss components. A splice serves as a critical junction point where two members are joined end-to-end, typically reinforced with nail plates or specialized connectors to maintain structural integrity. In larger truss systems, splices facilitate the efficient transportation and assembly of oversized components that would otherwise be impractical to manufacture or transport as single pieces. Proper splice design and installation are vital for load transfer, requiring precise engineering calculations to guarantee the connection achieves equivalent strength to a continuous member.

Top Chord

The top chord forms the primary load-bearing member along the upper perimeter of a roof truss, carrying the dead loads of roofing materials and live loads from environmental factors like snow and wind.

This critical component typically consists of dimensional lumber sized according to span, slope, and loading requirements. It connects to the bottom chord at the heel and meets opposing top chords at the apex. The top chord must be designed to resist both compression and bending forces while supporting purlins and roof sheathing. Proper nail plate connections at joints guarantee load transfer between intersecting members, maintaining structural integrity throughout the roof system.

Wall Plate (Bearing)

Proper load transfer from roof trusses to foundation walls relies on a well-designed wall plate system. The wall plate, typically a horizontal timber member, sits atop the load-bearing wall and provides critical bearing support for truss heels. Industry standards require minimum bearing lengths of 75mm to prevent localized failure and guarantee uniform load distribution.

Cost-effective wall plate installations utilize treated lumber to prevent rot and maintain structural integrity. Correct specification of wall plate dimensions and fastening methods considerably impacts overall system performance. Engineers must account for lateral thrust forces and verify adequate anchoring to resist wind uplift loads while maintaining proper load paths through the structure.

Web Runners

Longitudinal stability in roof truss systems relies heavily on web runners, which connect adjacent truss webs to provide essential bracing and load distribution. These horizontal members greatly reduce installation costs by minimizing the need for additional diagonal bracing while ensuring structural integrity across multiple trusses.

Web runners transfer lateral forces between trusses, preventing individual web members from buckling under compression loads. Strategic placement optimizes material usage and maximizes system performance. Industry standards typically specify web runner positioning at critical stress points and near major joints. Proper installation requires precise alignment and secure fastening to maintain designed load paths through the truss assembly.

Webs

While web runners provide lateral stability between trusses, internal web members serve as primary load-bearing components within each individual truss. Webs consist of diagonal or vertical members strategically positioned between top and bottom chords to transfer and distribute loads effectively throughout the truss system.

These internal members greatly reduce material costs by enabling wider truss spacing while maintaining structural integrity. When properly engineered, webs optimize force distribution, preventing chord deflection and ensuring maximum load capacity. Secured with nail plates at each joint, web members form critical triangulated patterns that determine the truss’s overall strength-to-weight ratio and cost-effectiveness.

What's Next?

Ready to discuss your metal building project? ROI Metal Buildings delivers cost-effective structural solutions that can save you 20-30% compared to traditional metal building systems. Our expert team specializes in comprehensive truss design, from apex to wall plate, ensuring maximum efficiency and structural integrity.

Contact ROI Metal Buildings today:

- Get a detailed cost analysis

- Receive custom truss specifications

- Start saving on your construction project

Call 865-855-9095 or contact us now to request your free quote and consultation.

Request A Quote Today!